by article post | Jan 16, 2025 | Plastic Mold

Custom acrylic display cases have gained immense popularity in various sectors due to their versatility, durability, and the aesthetic appeal they offer. Acrylic, commonly known as plexiglass, is a clear, lightweight material that serves as an ideal option for...

by article post | Jan 7, 2025 | Plastic Mold

When comparing polycarbonate and acrylic, two popular transparent plastics, several important differences emerge, affecting their suitability for various applications. Both are clear, lightweight, and shatter-resistant, but polycarbonate is significantly stronger and...

by article post | Dec 27, 2024 | Plastic Mold

High volume injection molding is one of the most effective methods for manufacturing plastic components in large quantities. It is widely used across industries due to its efficiency, precision, and scalability. From automotive parts to consumer electronics, this...

by phillipstool_n1ocsh | Oct 21, 2024 | Plastic Mold

Plastic injection molding has long been a cornerstone of modern manufacturing. Its ability to produce high volumes of complex parts with excellent precision, consistency, and speed has made it an attractive method for industries ranging from automotive to consumer... by phillipstool_n1ocsh | Jun 9, 2019 | Plastic Mold

For demanding parts that require high resistance to heat, corrosion, conduction, wear, friction, pressure, and water, Ceramic may be the material solution you’ve been looking for. Combining the benefits of ceramic materials with those of injection molding,... by phillipstool_n1ocsh | Jun 9, 2019 | Plastic Mold

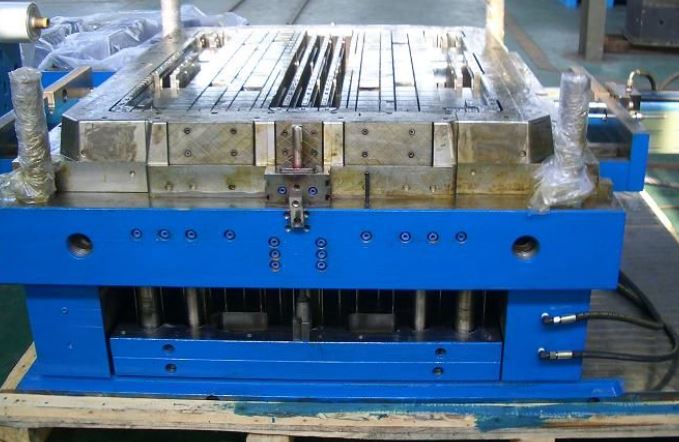

Phillips’ in-house plastic mold capabilities include rapid prototype, prototype, market-entry, and production tooling. The Company has the capability to design, build, and maintain complex tools creating an unbeatable advantage including maximum part-to-part...