by article post | Mar 8, 2025 | Plastic Mold

Aluminum sand casting is a widely used process for manufacturing complex aluminum parts by pouring molten metal into sand molds. This method is known for its cost-effectiveness, versatility, and ability to produce large and intricate components with excellent...

by article post | Mar 3, 2025 | Plastic Mold, plastic tooling company

LM25 aluminum alloy is a widely used material known for its high strength, corrosion resistance, and excellent casting properties. It belongs to the aluminum-silicon (Al-Si) family, which is favored for its lightweight nature and durability. The alloy is commonly used...

by article post | Feb 22, 2025 | Plastic Mold

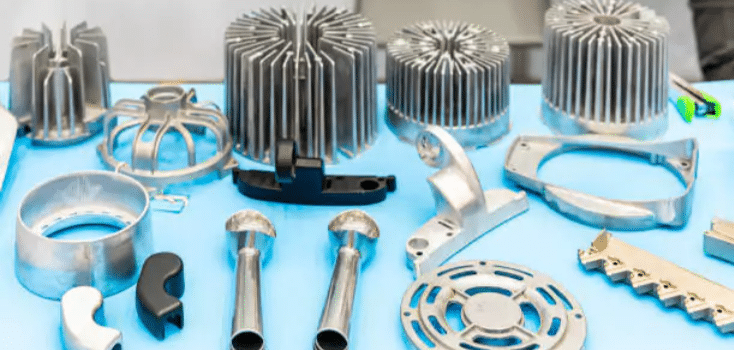

Aluminum die casting is a highly efficient and widely used manufacturing process that produces complex, lightweight, and durable metal components with high precision. It involves injecting molten aluminum into precision-engineered steel molds under high pressure,...

by article post | Feb 9, 2025 | Plastic Mold

Insert molding is a widely adopted manufacturing technique in the plastics industry that allows for the integration of various materials into a single, cohesive part. By inserting a preformed part—often made of metal, though sometimes plastic or other materials—into a...

by article post | Feb 3, 2025 | Plastic Mold, plastic tooling company

Injection molding is one of the most widely used manufacturing processes for producing plastic products on a large scale. At the heart of this process are plastic pellets for injection molding, which serve as the raw material that gets melted, shaped, and solidified...

by article post | Jan 29, 2025 | Plastic Mold

Plastic injection molding is one of the most widely used manufacturing processes for producing plastic parts in large volumes. It is preferred due to its cost-effectiveness, precision, and ability to create complex shapes. However, understanding the cost associated...