Phillips Tool & Mould was founded in 1975 in London, Ontario. We began by providing our customers with plastic molds and quickly built an international reputation for high-quality injection moulds and service at a fair price.

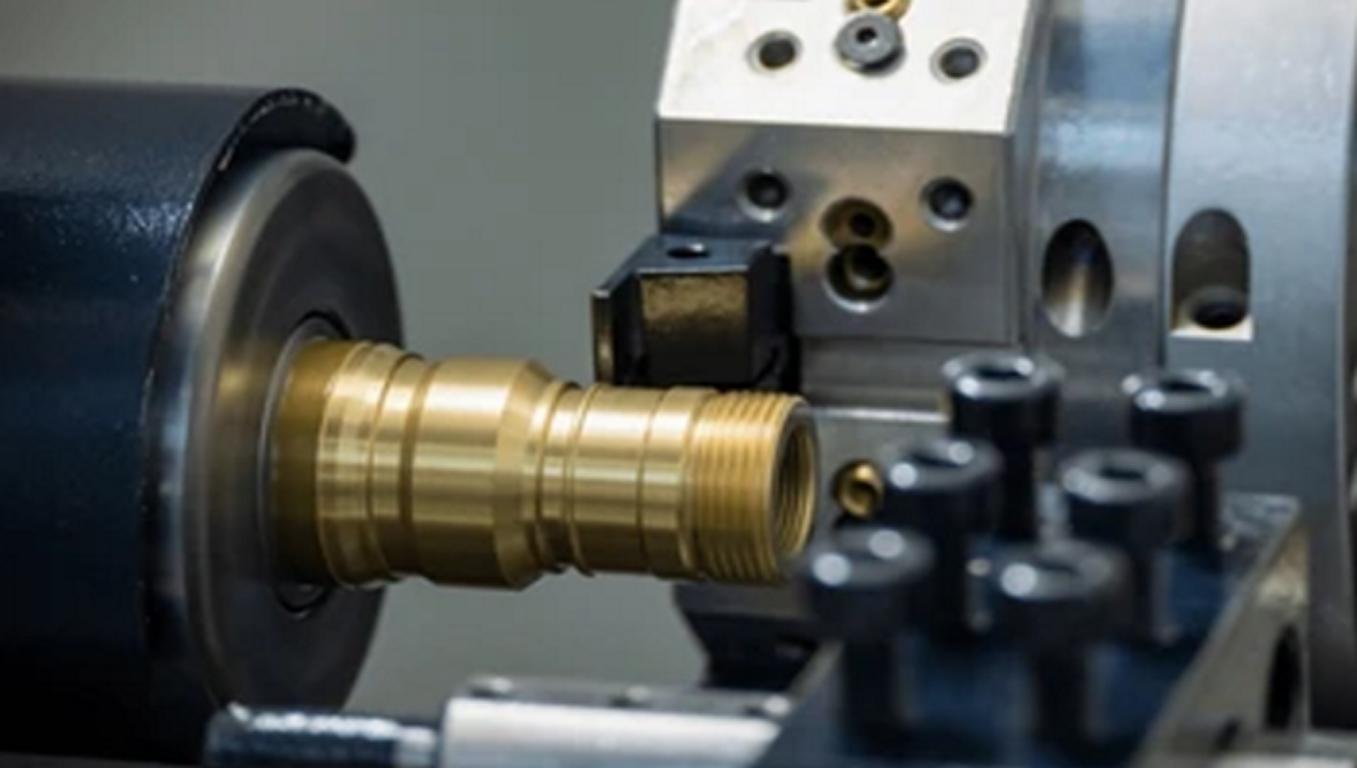

Our six divisions currently build a wide range of tooling consisting of injection moulds, compression moulds, rotocast moulds, pour moulds, fixtures and prototype tools. Our engineering, quality assurance, manufacturing and research and development expertise enable us to take a program from start to finish.

Our commitment to CAD/CAM allows us to design, update and respond quickly to customer engineering requirements. Our goal is to continue to redefine the tool build process to ensure improved tool production. By spending more time up front in tool development, we minimize the number of pre-production tool tryouts. Our experience in productionizing our moulds at customers’ facilities enables us to anticipate and recognize potential start-up problems before production begins.

Our engineering and design expertise in the initial program stages allows us to combine tool design with part feasibility to better meet the needs of our Customers. Quality, dedication and hard work are the key ingredients to success. We realize our reputation is on the line with every mould we deliver. Our objective is to build a custom plastic mold which produces high-quality parts which continue to meet the specification required by your customers.

Phillips has come a long way in the past twenty-five years with our commitment to Quality, Research and Development. Many more advances are anticipated as we meet the challenges of the future.r remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.